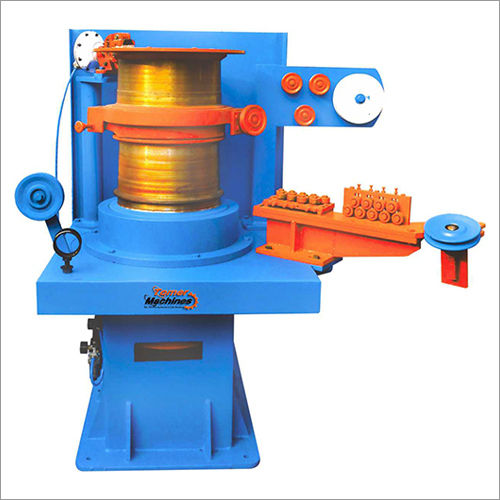

Intermediate Copper Wire Drawing Machine

500000.00 - 1500000.00 INR/Unit

Product Details:

- Production Speed 1200 m/min

- Production Capacity 900 kg/h

- Voltage 380 V

- Function Intermediate Drawing of Copper Wire

- Manufacturing Year 2024

- Drawing Passage 9

- Max De-coiler Weight 800 kg

- Click to View more

X

Intermediate Copper Wire Drawing Machine Price And Quantity

- 500000.00 - 1500000.00 INR/Unit

- 1 Unit

- Stainless Steel

- 9

- Flood Lubrication

- PLC Automatic Control

- Emergency Stop and Safety Guards

- Less than 75 dB

- 1.2 mm

- 400 mm

- 3900 kg

- Alloy Steel

- 4300 mm x 1700 mm x 1800 mm

- Water Cooling System

- HMI Touch Screen

- AC Frequency Inverter Drive

Intermediate Copper Wire Drawing Machine Product Specifications

- 1200 m/min

- 380 V

- 900 kg/h

- Intermediate Drawing of Copper Wire

- 2024

- 9

- 800 kg

- 60 kW

- New

- 2.6 mm

- Intermediate Copper Wire Drawing Machine

- Wire Drawing Industry

- Copper

- Copper

- Stainless Steel

- 9

- Flood Lubrication

- PLC Automatic Control

- Emergency Stop and Safety Guards

- Less than 75 dB

- 1.2 mm

- 400 mm

- 3900 kg

- Alloy Steel

- 4300 mm x 1700 mm x 1800 mm

- Water Cooling System

- HMI Touch Screen

- AC Frequency Inverter Drive

Intermediate Copper Wire Drawing Machine Trade Information

- 2 Unit Per Month

- 1 Months

Product Description

Precision Engineering for Copper Wire Drawing

This machine is built with advanced technology, including a robust PLC automatic control system and an HMI touch screen interface. Its nine alloy steel capstans ensure consistent tension and wire guidance, while stainless steel die boxes prolong component life. These features are tailored for precise intermediate drawing tasks in copper wire production, resulting in high-quality output for industrial demands.

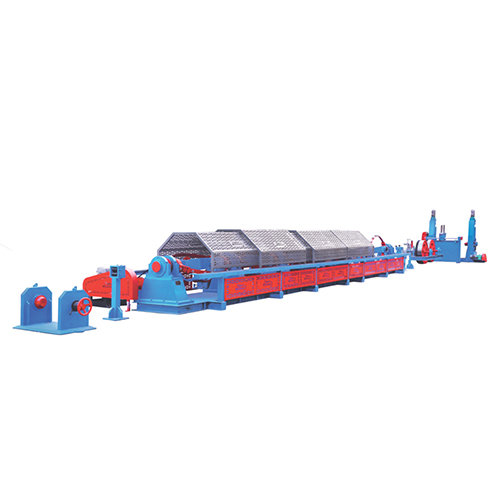

Efficient Cooling and Lubrication Systems

A water cooling system and flood lubrication provide superior temperature regulation and reduce friction during wire drawing. This enhances productivity by minimizing maintenance needs and preserving both wire quality and machine lifespan. Customers benefit from stable, high-speed operation even during long production runs, ensuring maximum efficiency and reliability.

Safety and Control at Every Step

Operator safety is paramount, with integrated emergency stops and safety guards throughout the machine. The quiet operation (less than 75 dB) and ergonomic touch screen controls simplify monitoring and adjustments. The PLC-based system ensures precise process management, minimizing errors and downtime while maintaining consistent wire quality.

FAQ's of Intermediate Copper Wire Drawing Machine:

Q: How does the PLC automatic control system benefit the wire drawing process?

A: The PLC automatic control system allows precise management of machine operations, including speed, tension, and safety features. Paired with the HMI touch screen, it provides real-time monitoring and adjustment, resulting in reduced errors, greater consistency, and simplified troubleshooting during copper wire drawing.Q: What is the process flow for drawing copper wire with this machine?

A: Copper wire with a 2.6 mm inlet diameter is fed into the machine. It passes through nine drawing passages with alloy steel capstans and stainless steel die boxes, reducing the wire to an outlet diameter of 1.2 mm. The flood lubrication and water cooling systems maintain optimal conditions throughout, supporting production speeds up to 1,200 m/min.Q: When is the best application for this intermediate wire drawing machine?

A: This machine is ideal for use in the wire drawing industry when intermediate reduction of copper wire diameter is required, specifically from 2.6 mm down to 1.2 mm. It is best suited for high-capacity, continuous production environments that demand precise control and consistent output quality.Q: Where can this machine be installed and operated efficiently?

A: Thanks to its moderate size (4300 mm x 1700 mm x 1800 mm) and safety features, the machine can be installed in most industrial settings such as factory floors dedicated to wire manufacturing. It is suitable for operations in India as well as export markets, given its compliance with demanding industry standards.Q: What are the main benefits of the water cooling and flood lubrication systems?

A: The combination of water cooling and flood lubrication effectively maintains optimal operating temperatures and reduces friction. This results in less wear on the dies and capstans, longer equipment life, improved wire surface quality, and sustained high-speed production.Q: How does the machine promote operator safety during operation?

A: The machine includes emergency stop buttons and safety guards strategically placed around key moving parts. These safeguards prevent accidental injuries and enable prompt machine shutdown in case of unanticipated issues, making the work environment much safer.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free