Drop Coiler Wire Drawing Machine

1800000.00 - 5000000.00 INR/Unit

Product Details:

- Wire Material Mild Steel / High Carbon Steel

- Inlet Diameter 2.5 mm

- Function Automatic Wire Drawing and Coiling

- Drawing Material Steel Wire

- Drawing Passage Single

- Application Wire Drawing and Coiling

- Manufacturing Year 2024

- Click to View more

X

Drop Coiler Wire Drawing Machine Price And Quantity

- 1800000.00 - 5000000.00 INR/Unit

- 1 Unit

- Emergency Stop Enabled

- Floor Mounted

- Heavy Duty Steel

- Low

- Vertical Drop Coiler

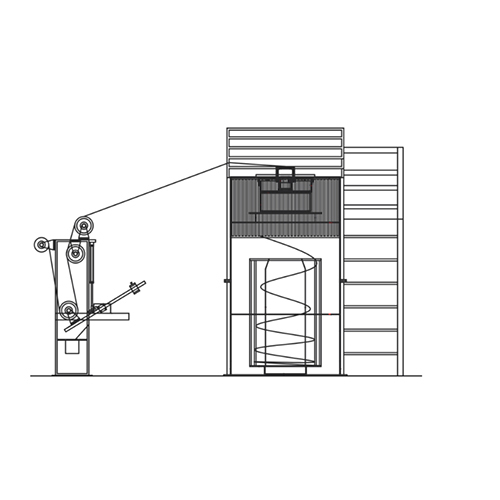

- 3200 × 1250 × 1900 mm

- 1800 kg

- Water Cooling

- PLC Controlled

- 0.8 mm

- Automatic Lubrication System

- AC Induction Motor

Drop Coiler Wire Drawing Machine Product Specifications

- 1200 kg/hr

- Drop Coiler Wire Drawing Machine

- New

- 380V

- 1000 kg

- 5.5 kW

- 60 m/min

- Single

- 2024

- Wire Drawing and Coiling

- Automatic Wire Drawing and Coiling

- Steel Wire

- Mild Steel / High Carbon Steel

- 2.5 mm

- Emergency Stop Enabled

- Floor Mounted

- Heavy Duty Steel

- Low

- Vertical Drop Coiler

- 3200 × 1250 × 1900 mm

- 1800 kg

- Water Cooling

- PLC Controlled

- 0.8 mm

- Automatic Lubrication System

- AC Induction Motor

Drop Coiler Wire Drawing Machine Trade Information

- 100 Unit Per Month

- 1 Week

Product Description

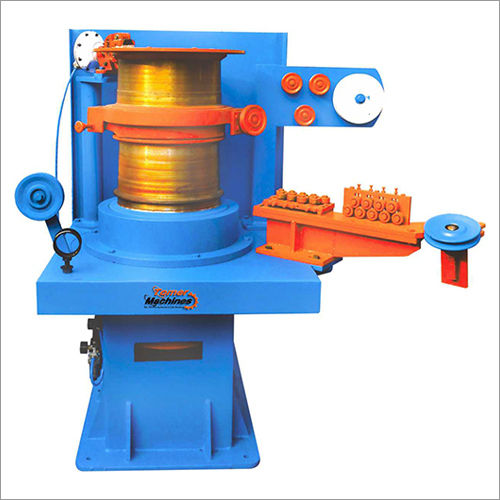

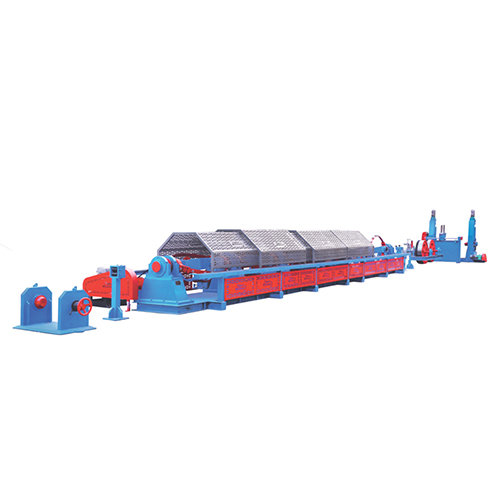

Drop Coiler Wire Drawing Machine designed by us, is used in the plastic goods sector to make hollow, solid round, or flat yarns from polyester, nylon, polyethylene, polypropylene, and polyester chips, among other materials. This machine is used in the bamboo and wood products sector to produce chopsticks, toothpicks, barbeque sticks, and other specialized equipment for reprocessing bamboo and wood wire. It uses no bending, no torsion, and powerful cooling technologies during the manufacturing process, resulting in wire with a low work hardening rate and exceptional toughness and ductility.

Advanced Control for Optimized Wire Drawing

The Drop Coiler Wire Drawing Machine uses a PLC control system, enabling accurate monitoring and adjustment throughout the production process. Operators can easily configure parameters for different wire types, benefiting from automatic responses that enhance efficiency and reduce downtime. This level of control results in consistent wire quality and streamlined operations.

Reliable Cooling and Lubrication Systems

Fitted with a water cooling system and automatic lubrication, the machine ensures optimal operating conditions even during high-speed production. These integrated features help maintain the wire's integrity while reducing wear on components, directly supporting long-term performance and minimizing maintenance requirements for users.

Robust Construction and Safety Assurance

Constructed with heavy-duty steel and floor-mounted stability, the machine offers longevity and operational safety. The inclusion of an emergency stop system provides immediate risk mitigation for operators, making it suitable for environments that prioritize worker protection and uninterrupted production flows.

FAQ's of Drop Coiler Wire Drawing Machine:

Q: How does the Drop Coiler Wire Drawing Machine operate with different wire materials?

A: This machine is engineered to process both mild steel and high carbon steel wires. Operators select the wire material during setup, and the PLC system fine-tunes the drawing process to ensure optimal output and coiling performance for each specific type.Q: What safety features are integrated into the machine for operators?

A: The Drop Coiler Wire Drawing Machine is equipped with an emergency stop button, robust heavy-duty steel frame, and automatic lubrication system, all designed to minimize risks and ensure a secure environment during operation.Q: When is it recommended to use this machine in wire manufacturing processes?

A: This machine is ideal whenever high-speed, precise, and automatic wire drawing and coiling are required, particularly for manufacturers producing large batches of mild steel or high carbon steel wire with diameters down to 0.8 mm.Q: Where should the Drop Coiler Wire Drawing Machine be installed for optimal operation?

A: It is floor mounted and should be installed in a well-ventilated industrial setting with access to a water supply for cooling and an appropriate electrical connection (380V) to ensure stable and safe operation.Q: What are the main benefits of using a PLC controlled wire drawing machine?

A: PLC control enables customizable settings, precise monitoring, and seamless automation, which enhance product consistency, reduce manual errors, and optimize energy efficiency throughout the wire drawing and coiling process.Q: How is the wire drawing and coiling process managed within the machine?

A: The machine features a single drawing passage with a vertical drop coiler that automatically guides wire from the inlet diameter of 2.5 mm to the outlet diameter of 0.8 mm. Coiling and lubrication are fully automated to streamline workflow and reduce operator intervention.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free