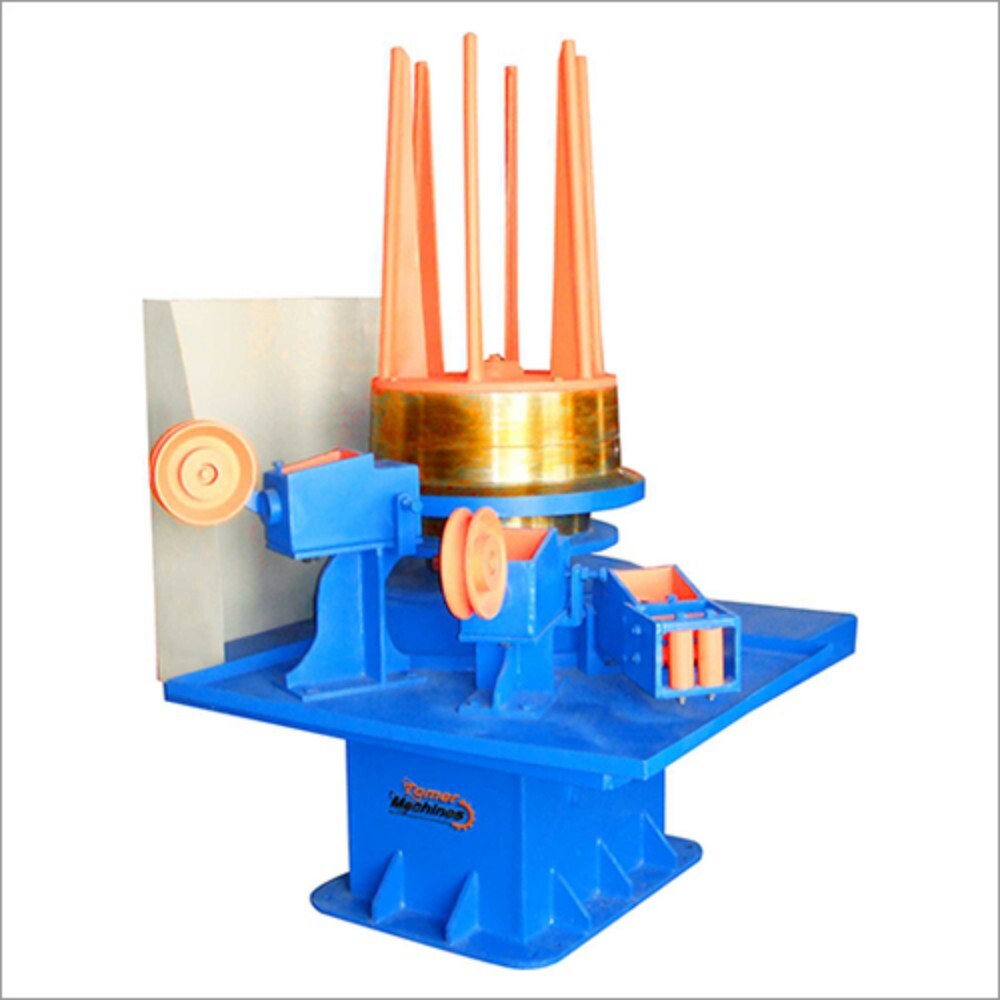

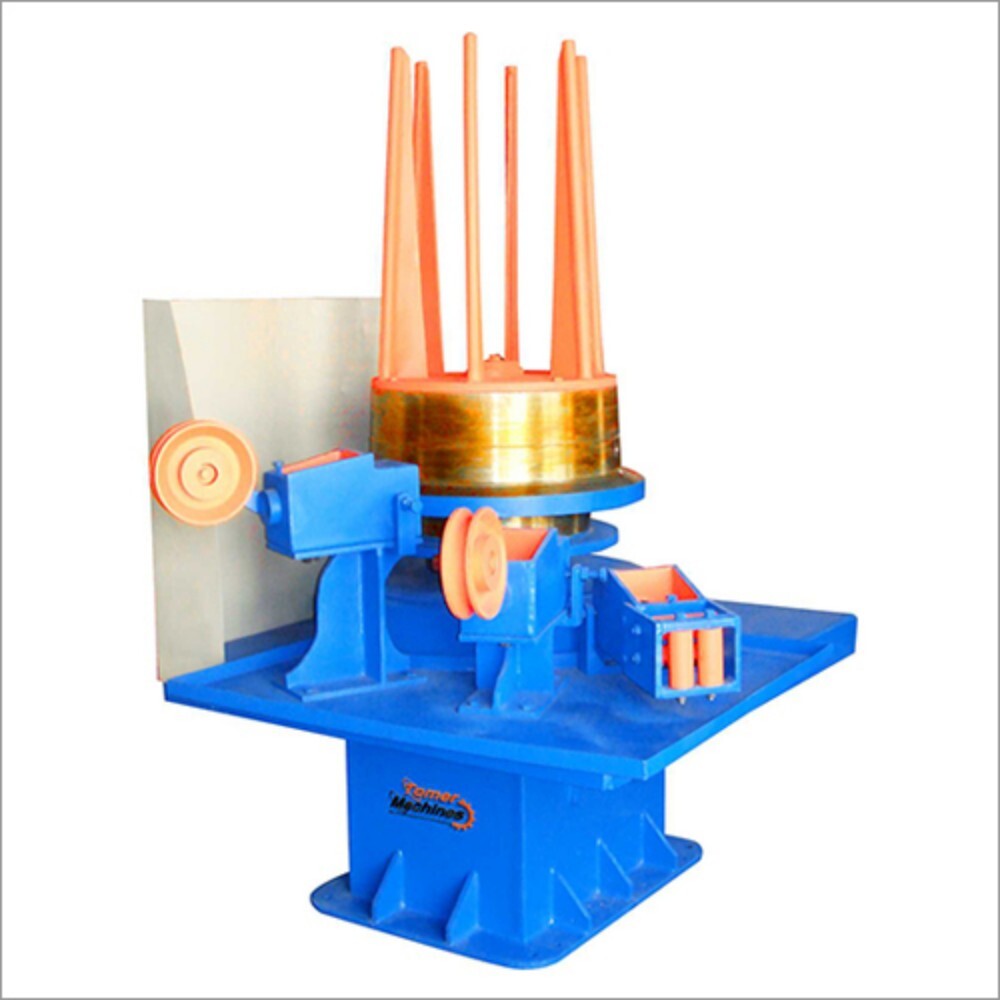

Aluminium Wire Machine

250000.00 - 1000000.00 INR/Unit

Product Details:

- Inlet Diameter 8 mm - 12 mm

- Manufacturing Year 2024

- Drawing Passage 6-8 Passes

- Function Drawing and Shaping Aluminium Wire

- Production Capacity 150-300 kg/hr

- Production Speed 8-12 m/s

- Product Type Aluminium Wire Machine

- Click to View more

X

Aluminium Wire Machine Price And Quantity

- 250000.00 - 1000000.00 INR/Unit

- 1 Unit

- Automatic or Manual Lubrication Option

- Spool Take-Up / Coiler

- Carbide / Alloy Steel

- Variable Frequency Drive (VFD)

- Digital / PLC Controlled

- Blue & Silver

- Heavy-Duty Steel Structure

- Water Cooling Tank Included

- 80 dB

- Approx. 1800 kg

Aluminium Wire Machine Product Specifications

- 380V / 415V, 3 Phase

- Aluminium Wire Machine

- 8-12 m/s

- 150-300 kg/hr

- Drawing and Shaping Aluminium Wire

- 6-8 Passes

- 2024

- 8 mm - 12 mm

- Aluminium

- Wire Drawing / Manufacturing

- 1200 kg

- 7.5-15 kW

- New

- Aluminium

- Automatic or Manual Lubrication Option

- Spool Take-Up / Coiler

- Carbide / Alloy Steel

- Variable Frequency Drive (VFD)

- Digital / PLC Controlled

- Blue & Silver

- Heavy-Duty Steel Structure

- Water Cooling Tank Included

- 80 dB

- Approx. 1800 kg

Aluminium Wire Machine Trade Information

- Cash Advance (CA), Cash in Advance (CID)

- Asia

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

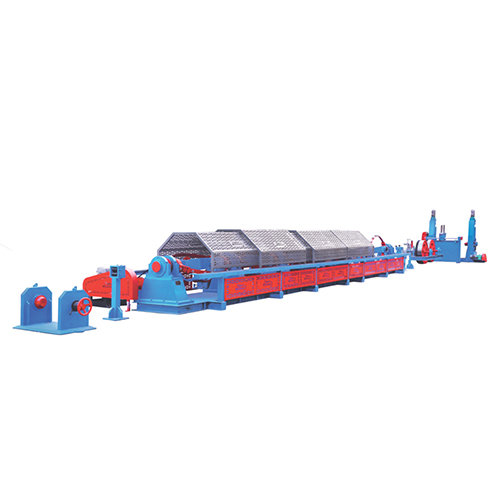

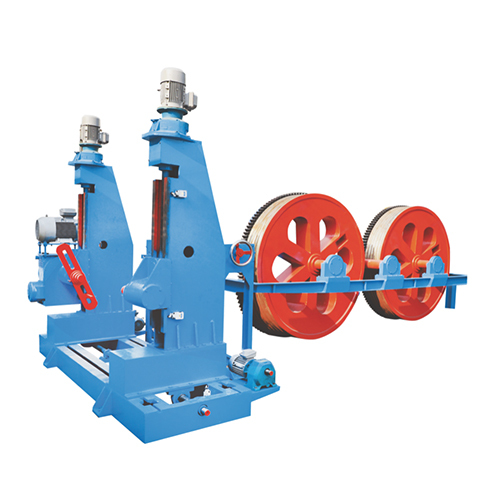

Product Description

We are an eminent supplier and manufacturer of Aluminium Wire Machine is made by using high quality required components with the help of innovative technology under the supervision of our experts. This item is utilized in the mechanical parts and electrical items for controlling the speed or machinery. It is high in quality and durability. The provided Aluminium Wire Machine is tested in the various quality parameters before dispatching it from our premises. We offer the same at fixed price rate.

Specification

Digital Precision and Optimized Speed

Equipped with a digital or PLC-controlled panel, this aluminium wire machine allows operators to adjust and monitor processes with remarkable accuracy. The integration of a VFD enables dynamic speed control, adapting to variable production requirements and increasing energy efficiency.

Advanced Lubrication and Cooling Systems

Choose between an automatic or manual lubrication system to ensure consistent performance and reduced maintenance. The built-in water cooling tank keeps operational temperatures in check, essential for prolonged machinery life and superior output quality.

Robust Build and Versatile Application

With a heavy-duty steel structure, this machine supports continuous operation under industrial conditions. Suitable for drawing and shaping aluminium wire, it is designed for manufacturers, exporters, and suppliers needing high volume, reliable output, and flexible configuration options.

FAQ's of Aluminium Wire Machine:

Q: How does the digital/PLC control panel benefit the wire drawing process?

A: The digital/PLC control panel facilitates real-time monitoring and precise adjustment of operating parameters. This enables consistent quality in aluminium wire production and simplifies troubleshooting and machine management.Q: What is the role of the Variable Frequency Drive (VFD) in this machine?

A: The VFD allows operators to regulate the machine's speed according to production needs. This not only maximizes efficiency and output but also ensures energy savings and reduced wear on mechanical components.Q: When should I choose automatic versus manual lubrication?

A: Automatic lubrication is recommended for busy production environments where minimal downtime is desired. Manual lubrication offers more direct control and is suitable when production runs are infrequent or highly customized.Q: Where is this aluminium wire machine typically used?

A: This machine is widely adopted in aluminium wire manufacturing plants, wire drawing facilities, and industrial workshops throughout India and global markets, thanks to its high production capacity and robust construction.Q: What is the production capacity and speed of the machine?

A: The machine can process aluminium wire at capacities ranging from 150 to 300 kg per hour, with production speeds between 8 and 12 meters per second. This makes it suitable for medium to high-volume manufacturing operations.Q: How does the water cooling system enhance the wire drawing process?

A: The integrated water cooling system maintains optimal temperatures during operation, preventing overheating and ensuring stable performance, which is essential for producing uniform, high-quality aluminium wire.Q: What are the main benefits of using this aluminium wire machine?

A: Key benefits include high efficiency, precise control, reduced operational noise (80 dB), robust durability due to heavy-duty construction, and flexibility to select options such as automatic/manual lubrication and various take-up systems to suit different manufacturing requirements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS