Product Description

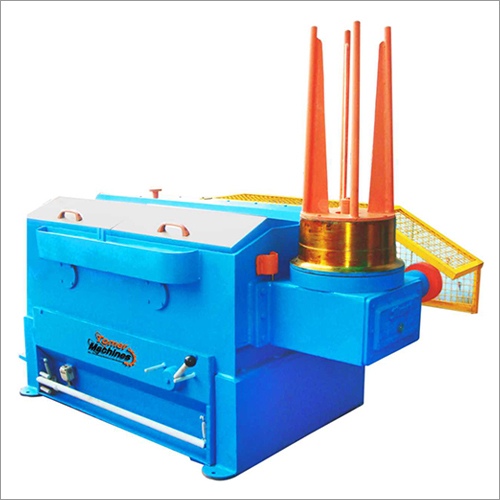

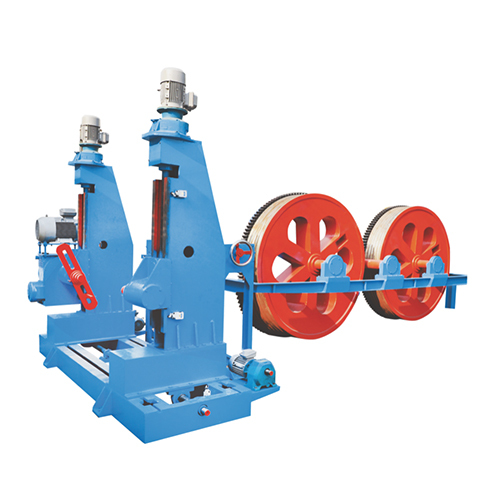

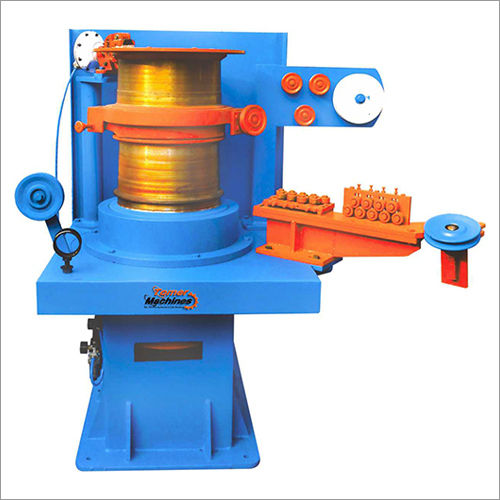

We are amongst the recognized manufacturers, suppliers and service providers of Industrial Wire Drawing Machine. We manufacture this Wire Drawing Machine using high grade quality raw materials. As to satisfy the increasing demands of our clients, these products are available in various specifications. These products are known for their durability, low maintenance and excellent performance. Industrial Wire Drawing Machine is generated to meet industrial standards. These Wire Drawing Machines are widely used in various automotive drawing machines and engineering industries.

|

Transmission method

|

Helical Gear Driven

|

|

Max cone diameter

|

250 mm

|

|

Frame

|

MS fabricated with precision

|

|

Shaft material

|

EN-19

|

|

Gear material

|

20 MNCR5

|

|

Capstan material

|

HCHCR/ Tungsten carbide coat (As per customer demand)

|

|

Bearing housing material

|

Solid Ci housing in divided construction

|

|

Gear terrain

|

25% dipped in Gear Oil

|

|

Drawing lubricant system

|

Wire drawing capstans and dies fully submerged, addition pressure Lubrication for die sat the inlet side if die holders

|

|

Die holder

|

MS with step type die holders, holder position set according to wire path

|

|

Drawing section

|

Separate, welded tanks in one block

|

|

Drawing capstans

|

4-step divided, wide rings with conical rolling surface

|

|

Handing

|

Optimum working height 85cms (easily accessible) inching pedals provided along with machine

|

|

Sealing of drawing sections

|

Gear separate housing 2 section system with rotary shafts seals and ring between the housing. Surrounded Areas-welded covers Body covers Double covers by stainless steel sheets.

|

|

Machine Model

|

TM/312/17/250

|

TM/312/17/250

|

TM/312/17/250

|

TM/312/17/250

|

|

Machine type

|

Cone type RBD

|

|

|

Cone type RBD

|

|

Suitable wire

|

CU/AL

|

MS/SS

|

CU/AL

|

MS/SS

|

|

Max drawing dies

|

17

|

17

|

21

|

21

|

|

Max drawing speed (mpm)

|

900-1200

|

750-900

|

900-1200

|

750-900

|

|

Intel size mm

|

1.60-3.25

|

2.00-2.60

|

0.290/0.600

|

0.360/0.475

|

|

Outlet size mm

|

0.40/0.800

|

0.50/0.650

|

0.290/0.600

|

0.360/0475

|

|

Suitable take up mm

|

400/500/630 Drop coiler

|

400/500/630

|

400/500/630 Drop coiler

|

400/500/630

|

Frequently Asked Questions:

1) What is wire drawing machine?

The wire drawing machine, makes wire drawing. Some portion of the steel wire pole as unrefined substance and lessens its measurement however much you need. It is the underlying machine, key to handle steel wire and metallic cross section in its various applications.

2) What is the course of wire drawing?

The wire-drawing process comprises of pointing the pole, stringing the sharp end through a kick the bucket, and joining the finish to a drawing block. The block, made to rotate by an electric engine, gets the greased up bar through the pass on, lessening it in measurement and expanding its length.

3) What is the upside of wire drawing?

The upsides of wire and pole drawing of different applications are: Great surface wrapping up. Flexibility to large scale manufacturing. Close layered control.

4) Which powder utilized in wire drawing?

Wire drawing powders fundamental parts comprise of modern soluble base, bath powder, stearic corrosive, cleanser, paraffin, creature oil, slaked lime, and thats only the tip of the iceberg. By and large, it is separated into calcium cleanser and sodium cleanser. The saponification response of white debris and unsaturated fat is liable for calcium cleanser.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free