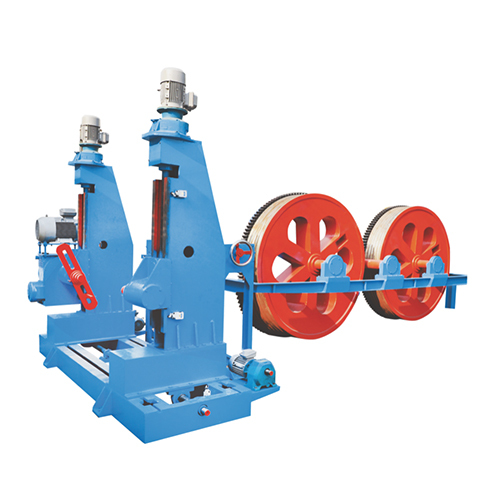

Automatic Intermediate Copper Wire Drawing Machine

300000.00 - 1500000.00 INR/Unit

Product Details:

- Application Wire Drawing

- Drawing Material Copper

- Condition New

- Product Type Automatic Intermediate Copper Wire Drawing Machine

- Voltage 380 V / 50 Hz

- Power 35 kW

- Production Capacity 800 kg/shift

- Click to View more

X

Automatic Intermediate Copper Wire Drawing Machine Price And Quantity

- 300000.00 - 1500000.00 INR/Unit

- 1 Unit

- 3600 mm x 1500 mm x 1600 mm

- Alloy Steel

- Automatic Circulating Oil Lubrication

- 4200 kg

- 1.2 mm

- PLC with Touch Screen

- Automatic Traversing Take-up

- Water Cooling for Capstan & Dies

- Overload Protection, Emergency Stop

- Alloy Cast Iron with Ceramic Coating

- 75 dB

- Inverter Motor Drive

- Annealed, Non-annealed Copper

Automatic Intermediate Copper Wire Drawing Machine Product Specifications

- 35 kW

- 800 kg/shift

- 2024

- 9

- 2.6 mm

- 900 m/min

- 1000 kg

- Copper Wire

- Intermediate Drawing, Wire Size Reduction

- Copper

- Wire Drawing

- New

- 380 V / 50 Hz

- Automatic Intermediate Copper Wire Drawing Machine

- 3600 mm x 1500 mm x 1600 mm

- Alloy Steel

- Automatic Circulating Oil Lubrication

- 4200 kg

- 1.2 mm

- PLC with Touch Screen

- Automatic Traversing Take-up

- Water Cooling for Capstan & Dies

- Overload Protection, Emergency Stop

- Alloy Cast Iron with Ceramic Coating

- 75 dB

- Inverter Motor Drive

- Annealed, Non-annealed Copper

Automatic Intermediate Copper Wire Drawing Machine Trade Information

- Cash Advance (CA), Cash in Advance (CID)

- 2 Unit Per Month

- 1 Months

- Asia

- All India

Product Description

Precision Engineering for Superior Copper Wire Drawing

Our intermediate wire drawing machine is tailored for processing copper wires from 2.6 mm down to 1.2 mm, enabling tight dimensional control across nine sequential drawing passages. Advanced materials, such as alloy steel die boxes and ceramic-coated capstans, ensure longevity and unwavering quality during operation. Suitable for both annealed and non-annealed copper, this machine supports diverse wire production lines in India.

Efficient Operation and Automated Control

Featuring a PLC-based control system with a touch screen, this machine simplifies management and optimizes wire drawing processes. Automatic traversing take-up and circulating oil lubrication reduce manual intervention and support continuous, high-speed production. Integrated inverter motor drive and comprehensive safety systems, including overload and emergency stop functions, protect both operators and the machine.

FAQ's of Automatic Intermediate Copper Wire Drawing Machine:

Q: How does the automatic circulating oil lubrication system benefit machine operation?

A: The automatic circulating oil lubrication keeps all moving parts constantly lubricated, significantly reducing friction and wear. This extends the lifespan of critical machine components, minimizes maintenance interruptions, and supports stable, long-term operation.Q: What types of copper wire can be processed with this drawing machine?

A: The machine is designed to process both annealed and non-annealed copper wires. This versatility makes it suitable for a wide range of industrial wire drawing applications, ensuring suitability for diverse production requirements.Q: When is water cooling applied during the wire drawing process?

A: Water cooling is continuously used to regulate the temperature of the capstan and dies throughout the entire wire drawing process. This prevents overheating, preserves the integrity of both components and copper wire, and ensures consistent output quality.Q: Where can this machine be installed and what are its space requirements?

A: Designed mainly for industrial setups in manufacturing, supply, and export businesses, the machine measures 3600 mm x 1500 mm x 1600 mm (LxWxH). It requires a dedicated, ventilated area with appropriate electrical connectivity (380 V / 50 Hz, 35 kW) for safe installation and operation.Q: How does the PLC with touch screen enhance machine usage?

A: The PLC control system with touch screen interface allows operators to easily set and monitor machine parameters. It simplifies operation, reduces training time, and improves troubleshooting and process control, resulting in more efficient and user-friendly production management.Q: What safety features are included in this wire drawing machine?

A: Key safety features include overload protection, which prevents damage from excessive loads, and an emergency stop button for immediate shutdown in urgent situations. These features help ensure operator safety and protect the equipment.Q: What are the key benefits of using an inverter motor drive in this machine?

A: An inverter motor drive provides precise speed control, energy efficiency, and smooth acceleration and deceleration. This leads to accurate wire drawing, reduced energy consumption, and prolongs the life of machine components.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free